By James Heinz

There is an old saying in the shipping business: “The ship doesn’t make any money while it is tied to the dock.” The bulk carriers of the Great Lakes could be loaded with iron ore quickly by using the oldest machine mankind has ever used to move things:

Gravity.

That left the problem of how to get the ore out of the ship’s hold. Originally ships were unloaded by men who shoveled the ore into wheelbarrows. It took five days to unload 400 tons by hand. Meanwhile the ship wasn’t making any money tied to the dock. A better solution was supplied by engineer George Hulett, who saw how long it took to unload ships in his home city of Ashtabula, Ohio. His solution:

The Hulett unloader.

Photo at top of page: Hulett unloaders – Milwaukee Public Library/Wisconsin Marine Historical Society

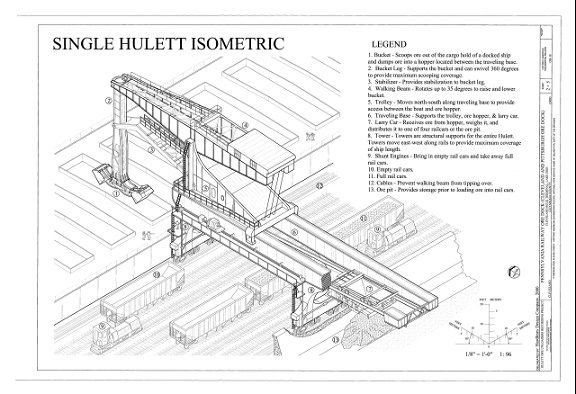

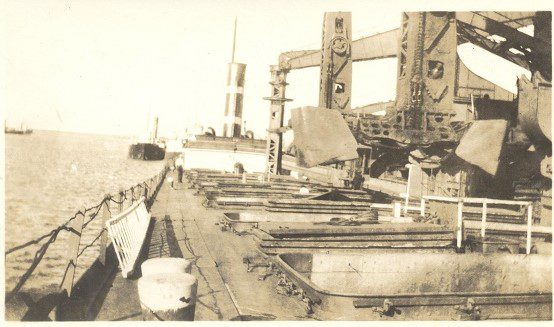

They were huge machines that looked like monsters from a sci-fi movie. To describe exactly how they worked would take half a page. Their size and operation can best be understood by viewing the attached photos and diagram and by viewing videos of them in operation on You Tube.

Single Hulett Isometric courtesy of Wikipedia

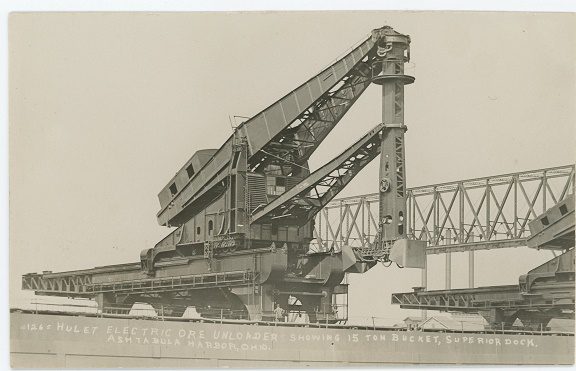

About 80 Huletts were built between 1898 and 1954. Almost all were used on the Great Lakes except one in New York City that unloaded garbage. Most were built on Lakes Erie and Michigan. They grew in capacity from 10 to 20 tons and could unload as much as 1,000 tons an hour. The Huletts made it feasible and economical for Great Lakes shippers to builder bigger and bigger bulk carriers and for the steel industry to greatly increase production.

Hulett electric ore unloader, 15 ton bucket, Superior Dock, Ashtabula, Ohio, 1909 – Milwaukee Public Library/Wisconsin Marine Historical Society

Hulett unloader inside the hold – Milwaukee Public Library/Wisconsin Marine Historical Society

They weighed as much as 1,500 tons. At first powered by steam, they eventually used electricity. They drew so much electricity that when they were in use, they caused the lights in town to dim, and each dock required its own electrical power plant.

Huletts working on the SULTANA at Cleveland – Milwaukee Public Library/Wisconsin Marine Historical Society

Starting in the 1980s the Huletts began to be replaced by self-unloading rigs carried on the ships themselves. This reduced the ship’s total cargo capacity. A ship that had previously taken 18-24 hours to unload using a Hulett unloader could be unloaded in six hours. The quicker turnaround time more than made up for the reduced load. No longer did the ship not make money while tied to the dock. It also enabled ships to unload in any port, whether it had Hulett unloaders or not.

Hulett bucket courtesy of Wikipedia

Hulett unloaders at Cleveland courtesy of the Library of Congress

The last Hulett unloaded its last cargo on December 15, 1992, at Whiskey Island in Cleveland. Ohio. The last two Hulett’s at Whiskey Island lingered disassembled for several years due to efforts to preserve them as monuments of industrial engineering but in 2024 Port Cleveland decided to sell them for scrap.

Once there were many, now there are none.

____________

James Heinz is the Wisconsin Marine Historical Society’s acquisitions director. He became interested in maritime history as a kid watching Jacques Cousteau’s adventures on TV. He was a Great Lakes wreck diver until three episodes of the bends forced him to retire from diving. He was a University of Wisconsin – Milwaukee police officer for thirty years. He regularly flies either a Cessna 152 or 172.